We need to know that the

globe valve can not be used in any pipeline. This article will talk about the knowledge of

globe valve.

The opening and closing parts of

globe valve are plug-shaped disc. The sealing surface is flat or conical. The disc moves in a straight line along the center line of the valve seat. It can be used to control the flow of air, water, steam, various corrosive media, mud, oil, liquid metal and radioactive medium. Therefore, this type of

globe valve is very suitable for cutting off or regulating and throttling. The opening or closing stroke of the valve stem is relatively short, and has a very reliable cut-off function. Moreover, the change of the valve seat opening is proportional to the stroke of the valve disc. And it is very suitable for the flow regulation.

Manual globe valve in sewage pipeline

Globe valve belongs to the block type valve, which mainly plays a cutting off role on the pipeline. Globe valve is one of the most used valves, and it is also the most suitable valve form for throttling. Because it has good regulation performance. Compared with other types of valves, the wear distribution around the valve seat caused by erosion is more uniform.

Globe valve is a forced sealing valve, so the pressure must be applied to the valve disc when closing so that there is no leakage between the two sealing surfaces. Because the sealing force and the medium pressure of the globe valve are on the same axis and in the opposite direction, the sealing force can not be amplified. But it can also overcome the pressure of the medium. Therefore, the sealing force required by globe valve is much larger than that of gate valve.

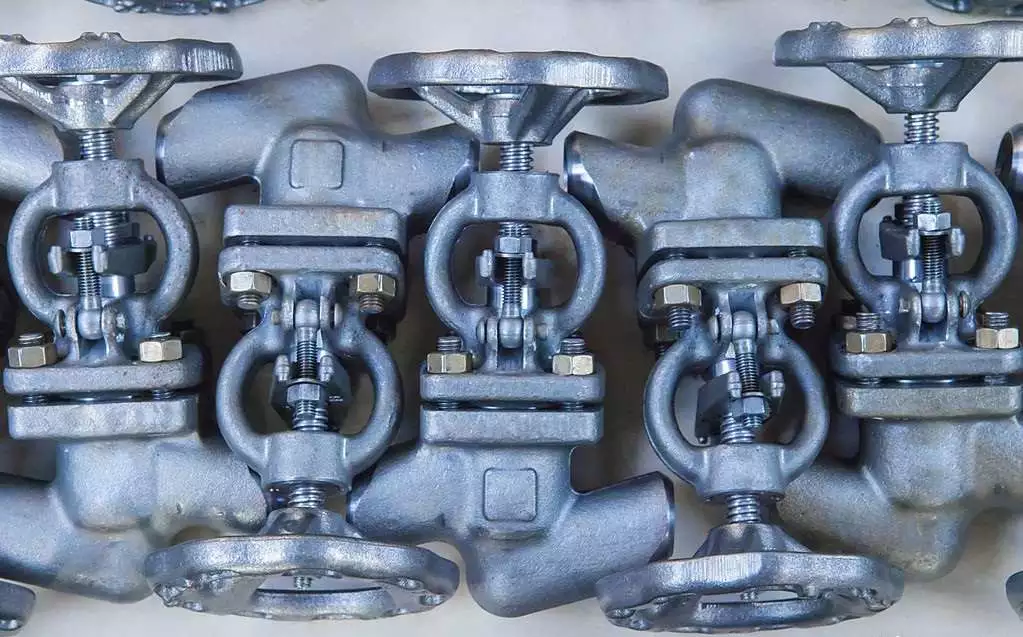

Forged steel welded globe valve

Special attention should be paid to the selection of globe valve. The globe valve with flat sealing ring can not be used for the medium with pollution or solid particles. In these media, it is more appropriate to use conical sealing surface for sealing.

In general, globe valves are recommended for throttling, regulating and high-pressure pipeline systems. Globe valves can be used in medium with double position recommendation, light structure requirements, no strict requirements on structure length, low pressure cut-off (small pressure difference) and high temperature medium. Globe valves are not selected as far as possible in mud, medium containing solid particles, wear resistance, diameter shrinkage, rapid action and small operation force When the sealing performance is good, high pressure cut-off (large pressure difference), low noise, cavitation and vaporization phenomenon, a small amount of leakage to the atmosphere, abrasive medium, low temperature and deep cooling, the globe valve with special design structure can be used.

Flange globe valve in pipeline

Globe valve also has an important feature, that is, the valve stem can be sealed with bellows instead of packing seal to form bellows globe valve. Bellows globe valve is suitable for flammable, explosive, toxic, very pure media, but also can meet the requirements of vacuum system.

However, the globe valve also has its disadvantages, which are mainly caused by the internal shape of the valve body. In the body cavity of the globe valve, the flow of medium changes from horizontal straight direction to upward or downward vertical flow, and then to horizontal direction flow. It can result in pressure loss, especially in hydraulic device. This kind of pressure loss should be paid enough attention to.

High pressure globe valve on oil pipeline

As one of the most important block valves, globe valve plays an important role in the field of aerospace. As an important component of aerospace equipment, globe valve realizes the functions of medium transportation, cut-off and adjustment, and its sealing performance directly affects the safe and reliable operation of space equipment. The research on the influencing factors and rules of sealing characteristics of typical globe valves is of guiding significance to the structural design of valve sealing pairs, so as to improve the sealing performance and reliability of valves.

The use of globe valve is very common. However, due to the large torque required for opening and closing and the long structure length, the nominal diameter is usually limited to DN250mm.