Nine types of valves - working principles, pros and cons (part two)

Posted: 11/02/2018 13:45:49 Hits: 373

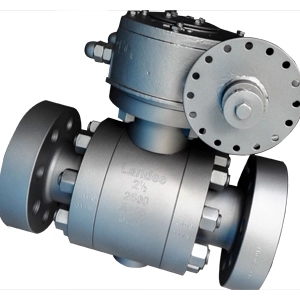

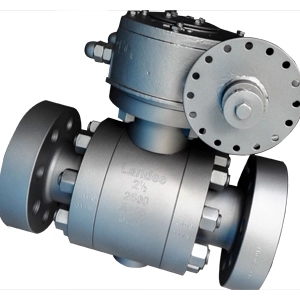

Ball Valve

Evolving from plug valves, ball valves are a kind of quarter-turn valves whose disc is ball shape. They are mainly used for blocking off, distributing and changing the direction of flow, of which, ball valves with V-type opening have a better flow rate moderating function.

Advantages:

• The lowest flow resistance (zero)

• Ball valves won't get stuck during working even without lubricant, so they are reliable for controlling the flow of corrosive and low-boiling-point media

• Fully sealed ability under conditions with relatively high pressure and temperature

• Fast shut-off (speeds of some structures are merely 0.05-0.1s), no impact when automatic system operating

• The disc can automatically position on the margin

• When fully opening or closing, the sealing surfaces of the ball and valve body are separated with the medium, so the sealing surfaces won't be eroded when the medium is speedily passing the valve.

• Compact structure, lightweight - so it is considered as the most suitable valve for low-temperature system.

• Symmetrical shape, especially welded body, being able to withstand the pressure from pipeline

• Disc can withstand high-pressure difference when closing

• Ball valves with all-welded valve body can directly be buried in the ground, and prevent the inner part of valves from being eroded. Ball valves, whose service life can reach to 30 years, are an ideal option for petroleum, natural gas pipelines.

Disadvantages:

• The major material of the sealing ring of valve body is PTEF, which won't have chemical reactions with almost all other materials. In addition, PTEF has characteristics such as small friction coefficient, stable performance, aging resistance, being able to withstand a wide range of temperature, excellent sealing performance. But, its physical properties, including large expansion coefficient, cold stream sensitivity, poor thermal conductivity, restrain the design of valve body. As the material of sealing ring hardens, its sealing ability weakens. Moreover, PTEF is unable to with high temperature and can't be used in conditions with temperature higher than 180℃, otherwise the sealing part will deteriorate.

• Weak adjustment performance compared to globe valves, especially pneumatic or electric valves

Plug Valve

It is a rotary valve whose disc is plunger shape (cylindrical shape or conical shape), which can be rotated to control the flow of media. The working principle of plug valves is basically the same with that of ball valves, which evolves from plug valves and mainly used in oil field exploitation, and petrochemical field.

Relief Valve

It is a protective device for pressure vessel, equipment, or pipeline. When the pressure of equipment, vessel or pipeline exceeds the allowed value, the valve will automatically open and discharge media, so as to prevent the pressure continue to go up. If the pressure is lower than the allowed value, valve should close automatically and timely in order to guarantee safe operation of equipment, vessel or pipeline.

Steam Trap

Media like vapor, compressed air will generate condensate water during transporting that needs to discharge in time for stabilizing the working efficiency and operation of devices.

Steam traps have the following functions:

• To prevent vapor leakage

• To discharge air, or other incondensable gases

Check Valve

Check valves, which are also known as non-return valves, one-way valves, reflux valves, can be divided into swing type and lift type. They are a kind of automatic valves that open and close by the force produced by the flow of media. The main function of check valves is to prevent media from flowing backward, pumps and drive motor from reversing, vessel media from venting.