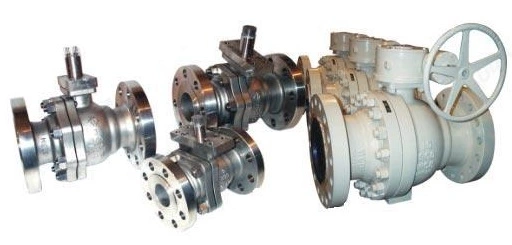

Metal sealing trunnion ball valve is the new generation of high performance ball valve, appropriate for long distance pipeline and common industrial pipeline. The strength, security and resistance to bad environment of ball valve are fully considered during design. Metal sealing trunnion ball valve can be used for both corrosive and non-corrosive media. Compared with floating ball valve, applied force on ball caused by fluid pressure before valve is totally transmitted to bearing, preventing ball from moving to seat and the seat cannot endure over high pressure, so metal sealing trunnion ball valve has low torque, few seat deformation, steady sealing performance and long service life, suitable for high pressure and large dimension. The valve has advanced spring seat components, having self-tightening and realizing upstream sealing. The ball valve has two seats which can seal every direction. So, the installation is not limited by flow direction.

Metal sealing trunnion ball valve generally adopts flanged connection. Butt welding connection is also adopted. trunnion ball valve is mainly applied in pipelines whose pressure is Class150~Class1500, PN16~PN100 and JIS10K~JIS20K. Applicable temperature is -196~350℃. Metal sealing trunnion ball valve is used to cut off or connect media in pipe. Made of different materials, metal sealing trunnion ball valve can be respectively applied in pipelines transmitting water, steam, oil, nitric acid, acetic acid, oxidant and urea. The ball valve is widely applied in petroleum refining, long distance pipeline, chemical engineering, papermaking, pharmacy, water conservation, electric power, municipal administration and steel.

Structural features of metal sealing trunnion ball valve:

Double block and emission

Trunnion ball valve adopts spring pre-tightening floating seat. No matter the valve is fully opened or closed, upstream and downstream seats block the fluid. Retentates remained in mesocoele of body is discharged by drain valve.

Automatic decompression

When temperature of media remained in valve rising, resulting in pressure growing abnormally, the pressure can be released automatically, only depending on functions of seat, without through safety valve, which is important for ensuring the safety when valve transmits liquid media.

Fire safety

Trunnion ball valve has fire safety. The design and manufacturing meet requirements of API 607 and API 6FA.

Emerging grease injection for sealing

When sealing on seat loses efficacy unexpectedly, which caused by foreign matters in media or fire disaster, grease injection valve can connect with grease injector quickly, rapidly and conveniently injecting sealing grease into sealing part of seat, remitting leakage.

Reliable stem sealing and low torque

Besides standard sealing ring, packing gland is also equipped with O-ring. Double sealing maintains reliability of stem sealing. Added graphite packing and sealing grease reduce the leakage of stem to minimum after fire disaster. Sliding bearing and thrust bearing on stem make valve operation more convenient.

Full bore or reduced bore

Full bore or reduced bore can be chosen based on demands. Aperture of full bore valve is the same as inner diameter of pipeline, convenient for pipeline cleaning.

Materials used for body of metal sealing trunnion ball valve

Commonly, WCB, CF8, CF8M, CF3, CF3M, C9, C5, C12, 310S and monel are used. The seat of metal sealing trunnion ball valve is made of carbon steel or stainless steel. The sealing face of seat has hardness and abrasion resistance. The seat made of Cr13 stainless steel should be heat treated. The seat made of carbon steel or stainless should be sprayed with Ni60.

The seat made of carbon steel, applicable for non-corrosive media whose temperature below than 425℃, including water, oil, gas and media containing tiny particles. If the seat is made of stainless steel (CF8, CF8M, CF3 and CF3M), the seat is used for corrosive or non-corrosive media under temperature below than 500℃, so as to the seat made of C9, C5 and C12. If the seat is made of stainless steel (310S), the seat is used for non-corrosive media under high temperature below than 800℃.

Metal sealing trunnion ball valve uses two-piece and three-piece body structure. The flange is connected by using bolt. The sealing adopts stainless steel ring inlayed with enhanced PTFE. Spring is set in the back of stainless steel, ensuring that seat can be closed to ball, maintaining sealing. Upward and downward stem is equipped with PTFE bearing, reducing friction and force for operation.